Selecting the Correct Sensor Size

Back to Selection Wizard

What do I do if my experiment’s contact area does not match the size of a SingleTact?

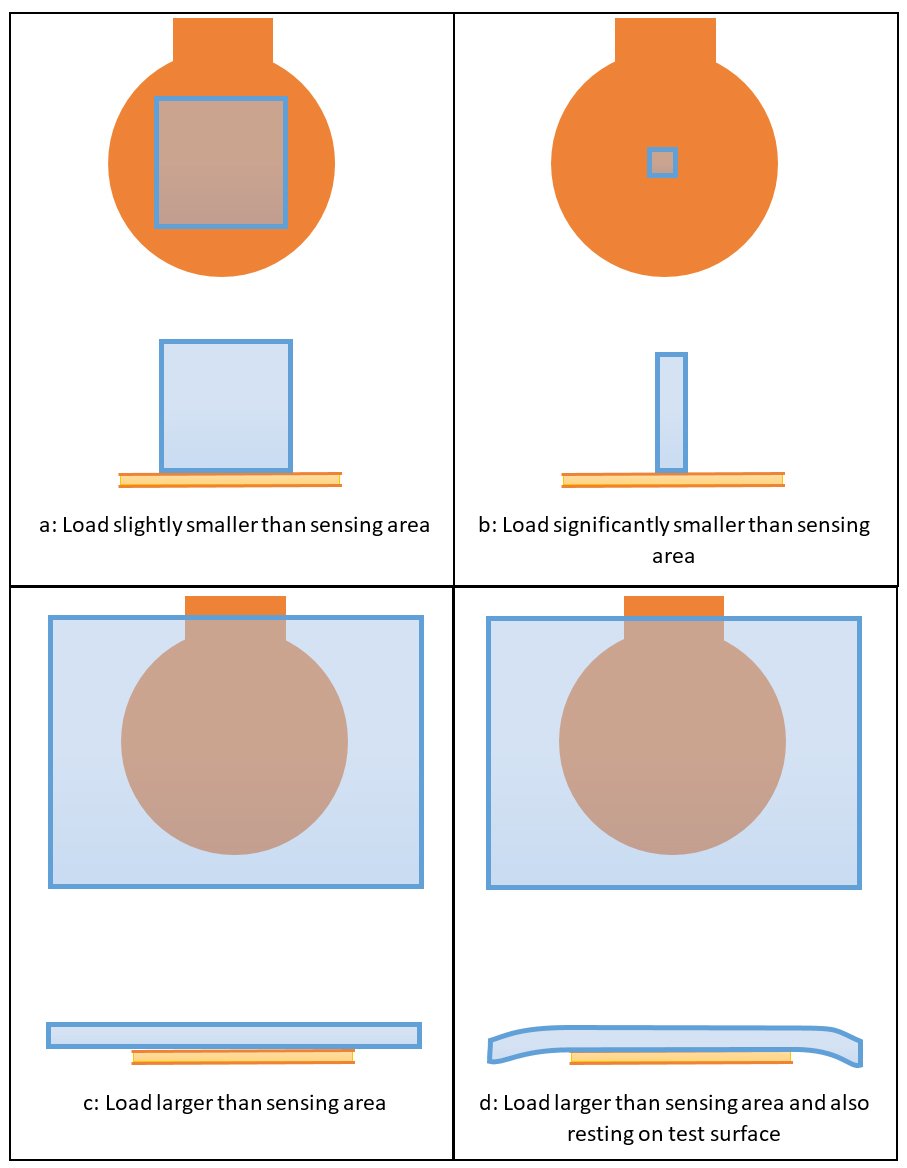

SingleTact performance specifications assume that the whole sensor is uniformly loaded, so the sensor should be chosen to match the force contact area. That said, useful measurements can still be performed in a number of situations. Consider the following four scenarios that show various loads resting on a SingleTact (from the top and from the side).

(a) Load slightly smaller than sensing area

SingleTact provides a good estimate of the applied force. Explanation: The SingleTact output is the integral of the applied pressure over the contact area. For a fixed load, the pressure increases as the contact area reduces (pressure = force / area), so in cases such as (a), SingleTact provides a good estimate of the applied force

(b) Load significantly smaller than sensing area

The internal mechanical structure of the sensor is slightly non-linear. If the load contact area is reduced to a value smaller than the sensor area, the sensor performance begins to deteriorate significantly from the documented specification. Also in extreme cases, as the localised pressure increases there is a greater risk of forming a highly concentrated point load and piercing the sensor.

(c) Load larger than sensing area

If the load is larger than the sensing area (c) SingleTact will report the correct force. However, this is only true if the load is not also resting on the test surface as in (d).

(d) Load larger than sensing area and also resting on test surface

In (d), only a fraction of the load is applied to the SingleTact sensing area so it will report artificially low.

Distributing the load

Note, it is possible to create a fixture to evenly distribute the load over the sensor, for example (e).